History of the Mill

The original production plant was built as a part of former Vítkovice Iron and Steel Works, where the first tube was made in December 1883 there, as a tube butt-welded in a gas furnace – it was the first ever tube made in the Austro-Hungarian Empire. Seamless tubes have been produced by the Erhardt method since 1896; in 1908, the Stiefel mill was put into operation under personal supervision of the inventor himself. During 1918 and 1919, the Big Mannesmann production line, together with converter and turning shop for threading the oil production tubes, were built. The production line came into service on the 4th September 1919. Between the years 1926 and 1927, the Small Mannesmann mill has been built and put to use. Both these production lines endured in the factory until nowadays.

The Mannesmann production line in Svinov has been a part of the company between 1947 and 1971. In 1962, the nondestructive testing of tubes also started that year. The cold drawing plant together with the Stiefel production line finished in 1997.

In 1999, the tube mill became a joint-stock company separated from the Vítkovice Group. Until September 2005, the sole shareholder was ASTONIA from the SHIRAN GROUP, the current owner is TŘINECKÉ ŽELEZÁRNY from the MORAVIA STEEL Group.

History of Seamless Tubes

The development of steam engines placed ever greater demands on the tubes. The pipes produced by welding no longer met these demands and new production methods had to be found. The brothers Reinhard (*1856, †1922) and Max (*1857, †1915) Mannesmann solved the problem in a brilliant way for their time.

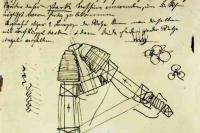

Sideway rolling process and corresponding mill has been patented under number 34 617 on 27th January 1885 and amended on 13th May 1887 by the patent no. 45 891. The significance of this patent can be illustrated by the fact that the technology is still alive and moreover perspective even after more than 100 years. The inventors did not intend originally to work on tube production technology and about the rise of this idea, two legends exist:

According to the first of them, the solution was closely connected with reeling technology used for smoothing and straightening of round steel, destined for the production of files. After the straightening and smoothing, pieces with flaws in the core came up. The same thing appeared during the cross rolling of round billets for flails and piston rods. The rolling was done on a stand – a reel with three rollers. It turned out that by replacing the third upper cylinder with a guide, a "loosening" effect was obtained, which led to the invention of sideway punching. The second version claims that Reinhard Mannesmann was playing with a piece of bread that he rolled between his fingers during a lunch. While playing with it, he got the bread against a toothpick he was holding in his other hand, creating a hollow pre-roll.

Probably the most objective is the opinion of Professor Franz Reuleaux (family friend and former teacher of the two inventors), who claimed at one of his lectures in Berlin, that the invention is a result of vehement thinking process and many experiments done during solving of numerous tasks submitted to them by their father.

First tests with tube rolling have been realized in Remsheid on the mill where the brothers produced files. The first semi-finished round bar came off in the night of 22nd August 1886. The very first seamless tubes have been produced by the sideway rolling in three production plants, in Bous (Saarland, Germany), Landore (England) and Chomutov (Czech Republic). They were looking for the way to produce lower diameter tubes with thinner wall. After several experiments, Reinhard Mannesmann placed a patent claim for "Method and equipment of forming, rolling and sizing of tubes and other hollow materials" in 1890 registered under patent No. 58.762 on 24th February 1891. It is said that by that time the new name for the technology originated. Professor Reuleaux called this rolling process a pilgrim mill, based on the procession march to the pilgrim place in Echternach (Luxembourg), where the Mannesmann family used to go. The first tube rolled so was of 68 mm diameter, 5 mm wall thickness and 4 m length.